Monitoring Construction Vibrations

Secant Piling Around the Colonial Transworks House “THE ONE” Skyscraper Project, Colombo, Sri Lanka

Background

Sri Lanka is redefining Colombo’s skyline by constructing one of Southeast Asia’s tallest buildings known as ‘The One’. Rising to a height of 376 meters, with 92 floors, The One Tower will be the tallest amongst a trio of skyscrapers being built adjacent to an important historic colonial building called the “Transworks House” built in 1908. This massive skyscraper project will be comprised of two luxury hotels (Ritz-Carleton and the JW Marriott), a large retail mall, a commercial office complex and 638 apartments, making it one of the biggest development projects within the region. The current trend of building tall skyscrapers calls for deep excavations and even deeper foundations, which can have damaging effects to a historical building. With the urban areas being the preferred place for these constructions, the awareness about building health monitoring becomes a crucial part to the planning stage.

Challenge

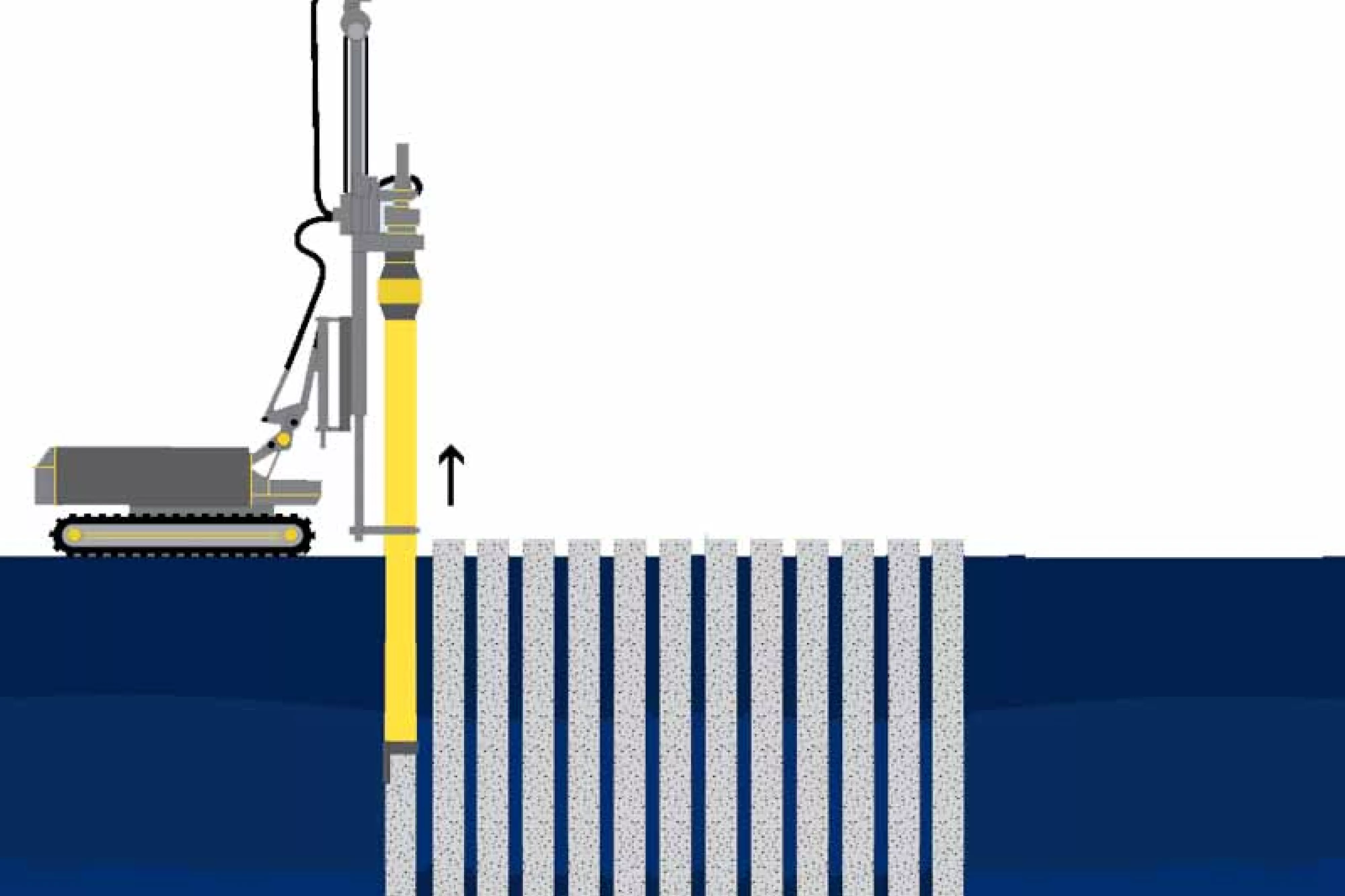

These three new skyscrapers are expected to each have an underground basement that could cause the land, on which the Transworks House is built, to collapse. The historic Transworks House was built using an old rubble technique and does not have the structural stability of modern steel frame buildings we see today. The decision was made to surround the Transworks House using piles to protect it from all construction activities. Although it was generally accepted that the bored piles would not create high vibrations, the secant pile design called for 1 meter of minimum rock socketing. This can create very high vibration levels depending on the depth and rock type.

Approach

Instantel’s Micromate seismic monitor was chosen to measure ground vibrations according to the Amended Air Blast Over Pressure (ABOP) and Ground Vibration National Standard of Sri Lanka which is based upon the ISO 4866:1990 (and updated to the ISO 4866:2010) Standard. The characteristics of this building fall into Type 4 “Structures declared as archaeologically preserved structures because of their sensitivity to vibration”. The Micromate monitoring unit was installed in seven consecutive locations throughout the Transworks House on two levels and one location near the piling machinery. The proximity constraints were very tight, the piles being very close to the foundation.

Results

The Micromate detected high vibration levels exceeding the expected thresholds. Thus mitigatory measures were required. Of the various options:

- Substitute the boring machine and reduce the depth of socketing.

- Control the vibrations by digging a trench around the foundation and filling it with sand to dampen the waves.

- Replace the core barrel’s bullet-teeth with slower advancing roller bits.

- Reduce the power and torque of the equipment.

- Coordinate real-time vibration monitoring to alert the machine operator to halt or adjust the drilling equipment if vibration levels exceeded their predetermined thresholds.

Option 5 was chosen as it could provide critical information in near real-time. Thus the contractor measured vibration levels with the supervision of an on-site engineer, inside the Transworks House. They repositioned the Micromate geophone to different places and elevations depending on the location of the pile being bored to understand the wave propagation throughout the building. The results were immediately analyzed by the engineer who then determined how much the applied boring pressure needed to be adjusted.

Conclusion

This direct feedback was crucial in allowing the contractor to remain on schedule and make dynamic changes on the machinery’s power, bore speed, and applied pressure to minimize vibration propagation and preserve the structural integrity of the historical Transworks House. By consistently monitoring the Transworks House during the pile driving, this phase of the project was successfully completed with no issues.