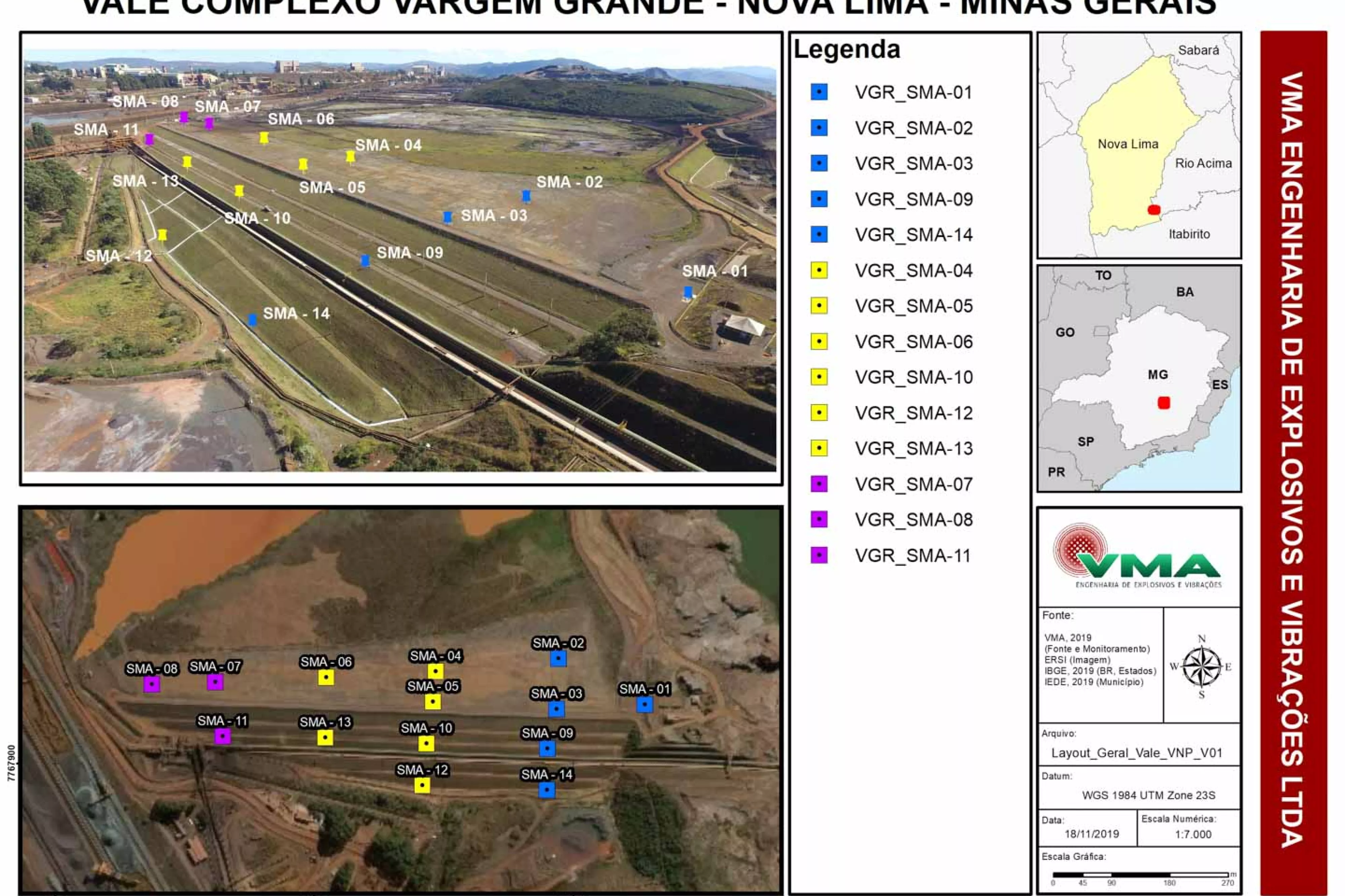

Vargem Grande Mine in Nova Lima, Brazil

How An Automated Remote Access Vibration Monitoring System Protects The Structural Integrity Of A Tailings Dam

Background

The Vargem Grande mine is situated in one of the most concentrated deposits of iron ore in the world. This fourth biggest mining operation contains an estimated 2.5 billion tonnes of potential iron ore.

Such large scale operations create a lot of unwanted residues, namely tailings. Tailings are the slurry of materials left over after the process of separating the valuable iron ore from the uneconomic gangue portion of the ore. This semiliquid mixture cannot be piled up like other mining by-products (Ex. overburden waste rock) but must be stored in pools or dams.

The viscous nature of these tailings and their residual concentrations makes them potential environmental hazards. Monitoring the structural integrity of the Vargem Grande tailings dam is, therefore, a high priority in protecting the mining operations and the well being of the neighboring populations.

Challenge

The purpose of these multiple installations is to protect the tailings dam overall structural integrity from various forms of vibration sources. These vibrations are generated by daily industrial mining activities and other sources such as the transportation of tailings into the reservoir via a conveyor belt, nearby blast detonations, as well as the movement of heavy-duty trucks and machinery.

Approach

Fourteen Micromate monitoring units were installed in a mesh formation along the 800 meters (2624 ft) of the dam to measure vibrations giving insight into the vibrational impacts along the dam structure, namely the land encompassing the beach (body and embankment) as well as the natural terrain.

Results

Measurements were recorded using Instantel’s Micromate monitoring systems in a continuous around-the-clock 24/7 configuration. Using Histogram-Combo mode, data volume was optimized while keeping track of complete waveforms when vibration levels exceeded industry-standard trigger levels. All data was continuously relayed to the South Geotechnical Monitoring Center using IP modems through a local telecom operator. It was found that the oscillatory disturbances from the conveyor belt were within limits and did not compromise the structural integrity of the tailings dam.

We work with Instantel units because they are easy to use, light to carry, and give trustworthy results, we love the reports and portable USB component.

Conclusion

The 14 Micromate monitoring units have provided ongoing surveillance data ensuring the safety of the operations. Mining activities from the conveyor belt, heavy-duty trucks and other machinery that produce vibrations are detected and relayed to the off-site managers using the remote relay stations to ensure the compliance standards for vibration monitoring are upheld.